About Die Casting

Die casting is a process where molten metal is injected into a steel mold under high pressure to create precise, detailed parts. It’s known for producing high-quality, consistent components quickly. This method is widely used in industries such as automotive and aerospace.

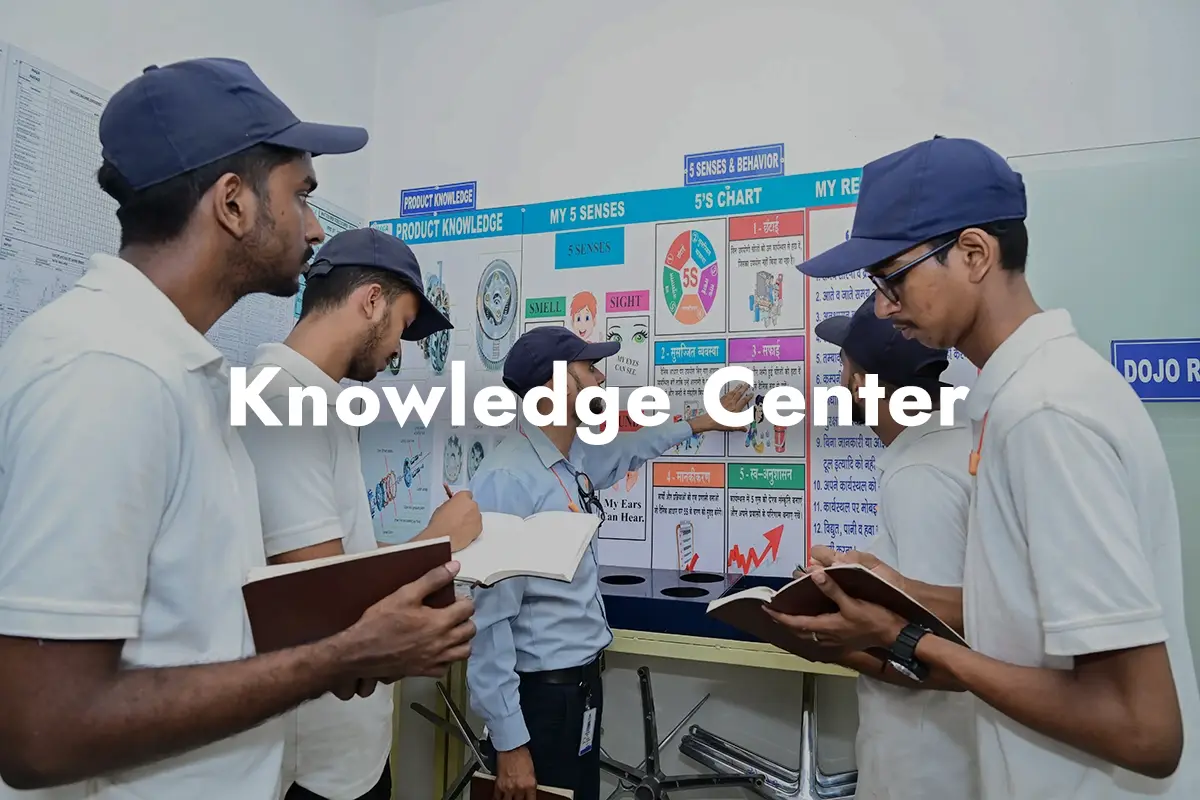

Dojo Room

Welcome to the Dojo Room within our aluminium die casting facility. This specialized room is designed to serve as a hub for technical training, quality control, and continuous improvement in the die casting process. The term "Dojo" reflects our commitment to mastering our craft with precision, discipline, and excellence.

Training Philosophy

The Dojo Room embodies our philosophy of excellence and continuous improvement in aluminium die casting. Our goal is to empower every team member with the knowledge and skills needed to excel in their roles, drive operational excellence, and contribute to the overall success of our facility.

Training Stations

The dojo room features multiple training stations equipped with advanced die casting simulations and real-world process models. Each station provides hands-on experience with aluminium die casting techniques, allowing operators and engineers to refine their skills and understanding of the process.

Safety Equipment

The room is equipped with personal protective equipment (PPE) and emergency response tools to ensure a safe learning environment. Safety is a top priority, and all training includes a focus on maintaining the highest safety standards.

Interactive Displays

Interactive displays and digital interfaces provide visual and auditory feedback during training exercises. These displays help illustrate complex concepts and enhance understanding through engaging, hands-on learning experiences.

Quality Control Stations

Dedicated areas within the dojo room are set up for quality control training. Here, trainees learn to use various measurement tools and techniques to assess the integrity and precision of die-cast components, ensuring they meet stringent quality standards.